Molson Coors G150 Project

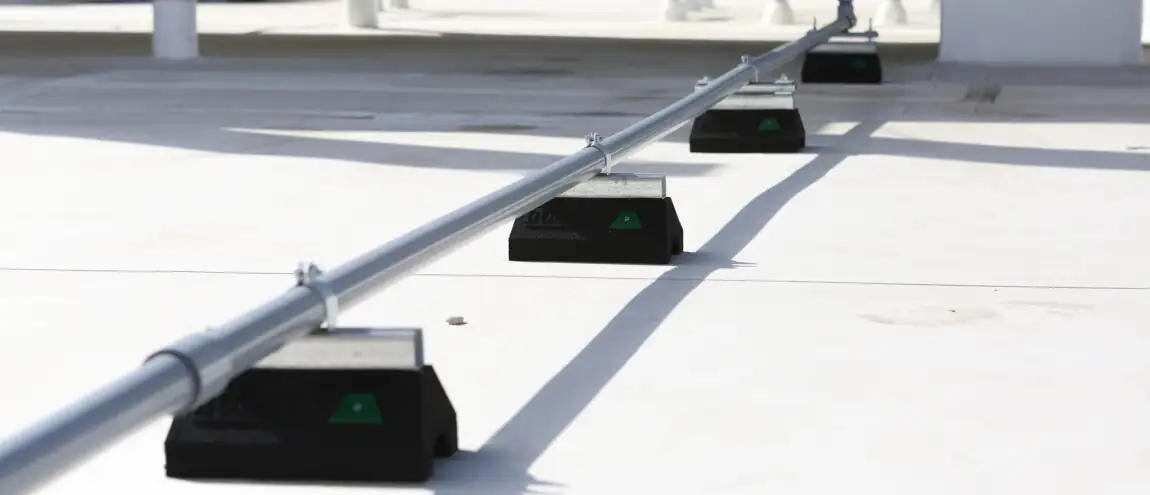

Douglass Colony Group played a pivotal role in the Molson Coors G150 Modernization project, delivering a comprehensive roofing solution for this state-of-the-art facility. Our team installed 149,242 square feet of 80 mil fleece black Elevate TPO roofing membrane across 16 distinct roof deck areas, ensuring top-notch protection and durability.

To enhance water drainage from the flat structural roof decks, we applied tapered insulation throughout the project. Despite the challenges of winter construction, we utilized temperature-controlled “hot boxes” to maintain optimal conditions for roofing materials, ensuring quality installation.

Working in tight spaces near fermentation tanks required innovation; we modified equipment with 100-foot-long heated hoses to facilitate precise roof installation in confined areas. Additionally, we insulated and detailed 10,266 linear feet of circular concrete curbs around 118 fermentation tanks with Elevate Flex TPO, streamlining the installation process.

Managing the roof areas where the fermentation tanks were situated involved navigating 3-foot thick concrete decks and 38% open space for tank cones. Our efforts contributed to a facility designed to significantly reduce energy usage by 15% and waste by 35%, showcasing our commitment to sustainability.

Collaborating closely with Haskell Architects and Hensel Phelps, we worked to achieve the project’s design intentions, demonstrating the power of teamwork in overcoming complex challenges.

The G150 project is a testament to innovation, problem-solving, and dedication to quality. Engineered to support over 100 fermentation tanks, the roofing system is a crucial component of Molson Coors’ operations, reflecting the exceptional craftsmanship of our team. This project not only modernizes brewing processes but also positions Molson Coors as a leader in environmentally responsible brewing, making it a model for future industrial construction projects.