Quality Design and Innovative Solutions

Commercial construction comes with a multitude of variables, and that list grows when the buildsite has installation restraints, specialty build design, and other logistical challenges. Developing in Downtown Denver is an undertaking very few general contractors are willing to attempt.

Anticipating problems before they occur requires a highly-experienced commercial construction company. As the sole contractor utilizing FRAMECAD in Denver and the Rocky Mountain region, Douglass Colony will not only eagerly take on the projects that others won’t, we’ll complete them safer, stronger, and quicker.

Douglass Colony is a specialty contractor with accomplishments including Meow Wolf Denver, VIB Hotel and Concourse A and B at Denver International Airport.

FRAMECAD FAQ

-

What is FRAMECAD?

FRAMECAD is a 30 year old New Zealand software and equipment company with manufacturing partners in over 60 countries worldwide. Douglass Colony was the first company to bring this advanced end-to-end steel frame design and manufacturing solution to the United States allowing us to produce panelized metal stud framing in a controlled factory setting.

-

When should FRAMECAD be brought in on a project?

FRAMECAD should be brought in early in the project to work directly with the architect and engineer to ensure the most efficient design. The FRAMECAD solution can improve every phase of the CFS framing process, even if it was not designed in FRAMECAD originally.

-

What part of a project can you frame with FRAMECAD?

With FRAMECAD you are able to design and build everything up from the foundation, including all load bearing and non-load bearing walls along with floor and roof trusses.

-

Can FRAMECAD handle multiple stories?

Yes. Mid-rise buildings (5 or 6 levels) in cold-formed steel are more common and economical and many have been constructed throughout for the past 20 or more years. FRAMECAD has the ability to go up to 12 stories of framing and possibly more depending on loads.

-

How does FRAMECAD affect the project schedule?

With FRAMECAD’s speed of production and ease of erection, framing can be completed in just ¼ of the time when compared to conventional framing. Douglass Colony can produce panel sizes limited only by shipping restrictions.

-

Building codes, UL, STC ratings?

- IBC: 2015 & 2018

- 1-3 hour UL fire assemblies for floor and ceiling

- STC ratings of 54 and greater

- ICC Certified

A Seamless Journey from Vision to Completion

Douglass Colony takes the project from CAD design to completed construction with fewer headaches, hangups or obstacles than standard commercial construction. From planning and designing, to prefabrication and throughout the construction phase, we take meticulous caution with every detail, from foundation to roof.

Our team supplies and installs cold-formed steel trusses, prefabricated light-gauge panels, metal framing and more. All work is done right here in our workshop, which means faster production times and much less time on-site building.

FRAMECAD’s cold-formed steel frame system enables architectural and design flexibility that delivers unprecedented precision, accuracy, and speed.

WHAT DOUGLASS COLONY CAN DO WITH FRAMECAD

The FRAMECAD system reduces build times by 75% with a fraction of the on-site construction time.

Design

- In-house expert FRAMECAD designers

- We will design a custom plan or we will adopt an existing design

- Precision software designs robust and reliable structures every time

- Engineer-sealed shop drawings included

Build

- Mass production of cold-formed steel frames and end-to-end steel frame connectors

- Requires only 1/4 of the in-field time of conventional framing

- Prefabricated stud wall panels

- Exterior and interior load bearing walls

- Non-load bearing back up framing

- Exterior curtain / by-pass walls

- Interior partitions

- Floor trusses in a multitude of depths and spans

- Roof trusses in a variety of profiles

- Blocking trusses

Build It Better Powered By FRAMECAD

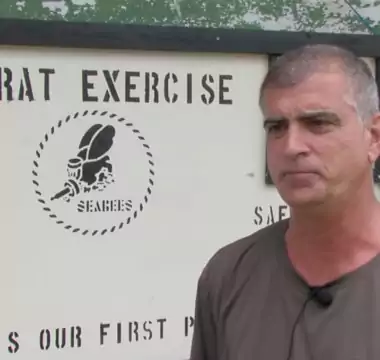

Hear what our FRAMECAD Division Manager, Joe Doxey, had to say when he was on the Build It Better podcast this summer. Together with host and construction industry veteran, Robert Johnson, Doxey discusses how FRAMECAD provides advantages for everyone involved in a project and how it can help the industry at large.

FRAMECAD In Action

Flexible. Fast. Strong.

The FRAMECAD system is a highly advanced end-to-end steel truss design and manufacturing solution that makes building commercial buildings in highly-populated cities like Denver possible like never before. It is a beacon for sustainable construction and the structural resilience of light gauge steel framing is ideal for withstanding the Rocky Mountain jetstream.

The system’s flexibility makes it an ideal solution for custom commercial architecture. The off-site construction of the building envelope is complete with weather-barrier sheathing and delivered ready to install. The engineering process creates load-bearing stud wall panels, exterior curtain wall systems, steel floor trusses, steel roof trusses — transforming the potential and possibilities of construction.

Delivering an impressive 25,000 engineering calculations per square meter of roof and walls in just seconds, the cold-formed steel (CFS) software allows us to finish builds, from design to completion, in a fraction of the time.

Efficiency is as crucial as craftsmanship, and at Douglass Colony our engineering and logistics team can deliver and erect prefabricated steel framing anywhere you need it. Reach out and set up a time to discuss your project — we love a challenge.

From CAD design to a fully constructed building, FRAMECAD’s panelized metal stud framing is changing the way construction is done. FRAMECAD’s cold formed steel frame system enables total architectural and design flexibility that is fast, cost effective, sustainable, and safe, all while being an exceptionally resistant and long-lasting option.

FRAMECAD Fast Facts

Quicker Builds

High quality results in just ¼ of the in-field time for any project.

Cost Effective

No high-skilled labor required.

Strong as Steel

Steel’s inherent strength allows for long spans with less material.

Durable and Sound

Exceptional fire, corrosion, and pest resistance.

1-3 Hour UL Assemblies

Accommodates any metal stud framing UL assembly.

PREFABRICATED

Versatile, precise, and pre-assembled.

The Benefits Of Steel

Increasing safety and structural building codes are driving up the demand for steel. As a result some contractors are facing delays in the supply chain and cost for building materials going up. More time and more money means less return on investment.

With prefabricated cold-form steel framing, much of that investment is returned with efficiency.

Douglass Colony is a steel truss manufacturer with a certified fabrication facility in Denver, Colorado. The engineering components for our truss systems are supplied by ITW TrusSteel, an industry leader in precision-driven steel framing systems. With the equipment, technology and experience the team at Douglass Colony are experts in design, fabrication and supply of light gauge steel roof trusses, metal framing, and sections.

Douglass Colony, as well as FRAMECAD, are “ICC-ES certified” under ESR-2361. Copy of the certification can be provided upon request.

Testimonials

The time saved and quality control of the Douglass Colony panelized system is beneficial for the entire project team– as it is cost effective, time efficient and allows versatility in fast track projects requiring field modifications at minimal impact to the system.